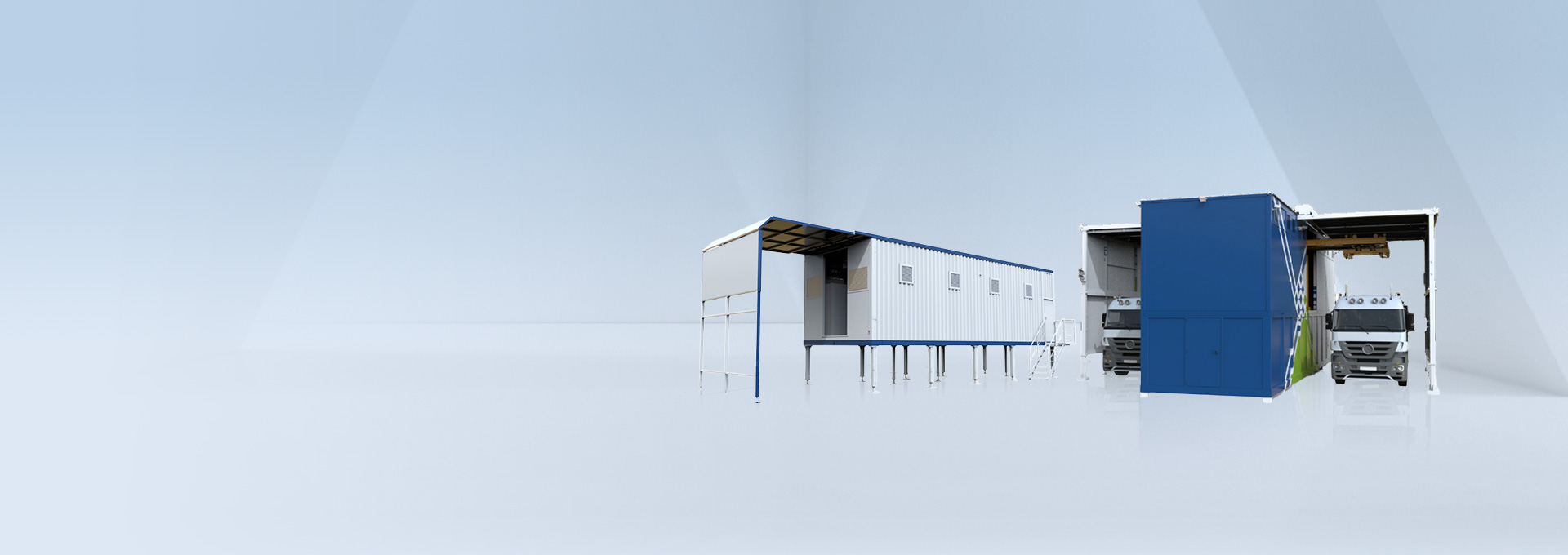

Fully compatible with mining truck battery boxes under 1000kWh

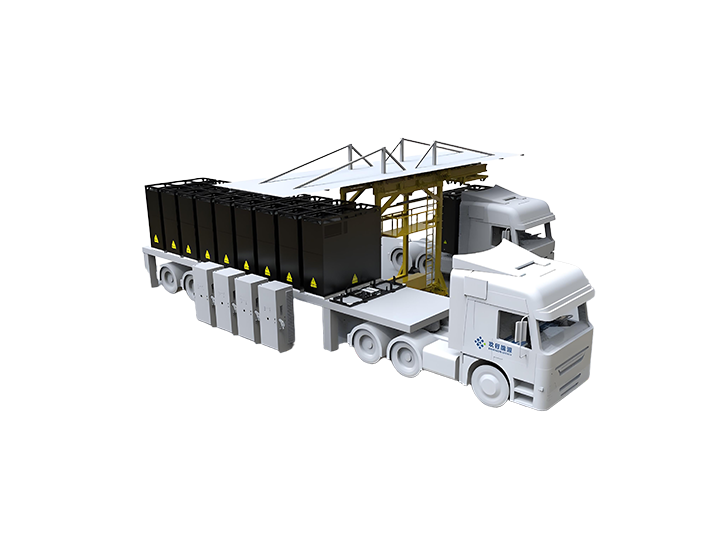

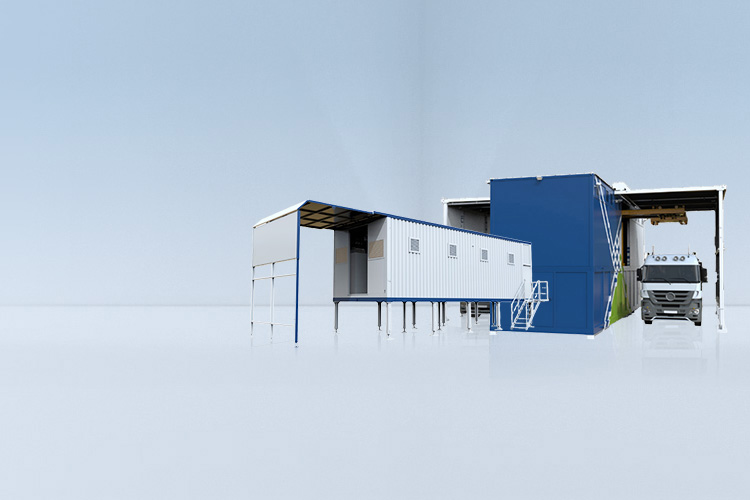

Supports unmanned mining truck battery swapping with canopy

Station and vehicle arranged parallel for easy entry and effortless parking

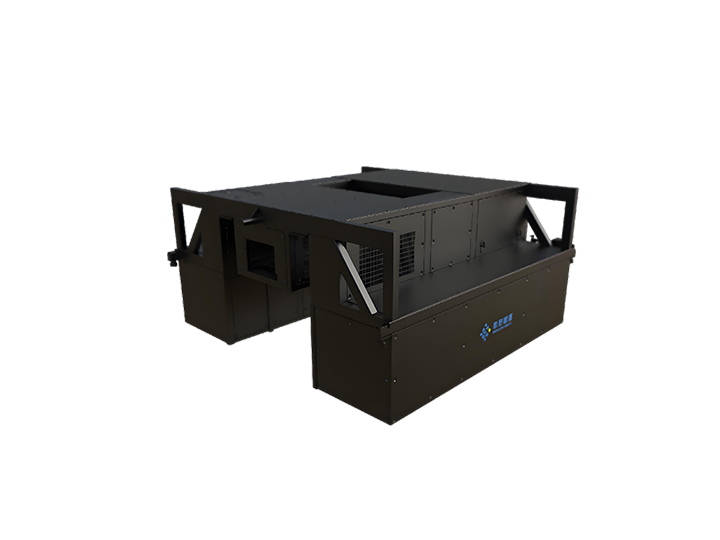

Separate charging and swapping infrastructure with minimal civil engineering requirements and no foundation pits

Scalable to 8/10/11 workstations

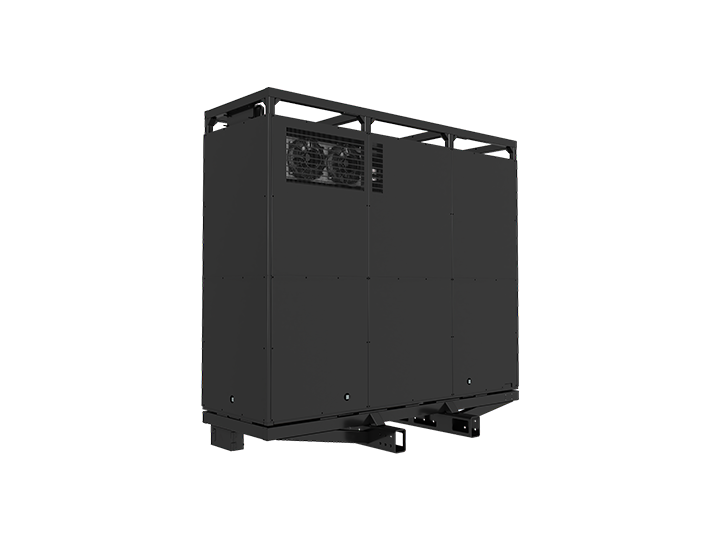

Mobile design, fast drop off, quick transition, and quick dismantling of stations

Flexible and diverse combinations, strong adaptability to different scenarios

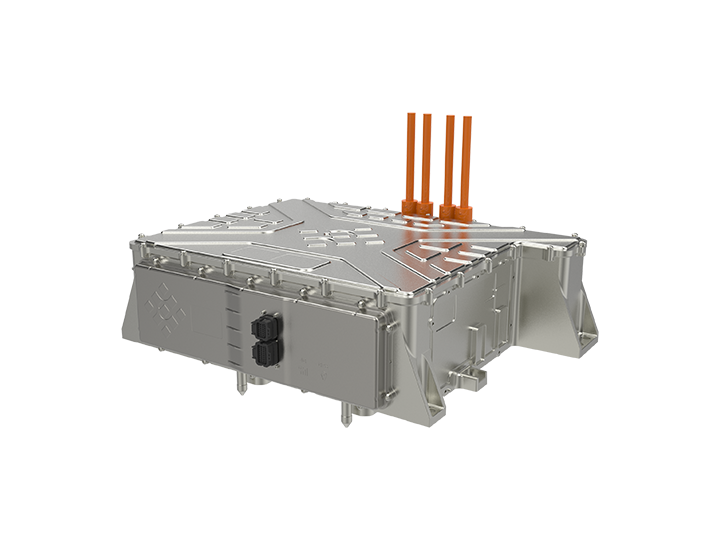

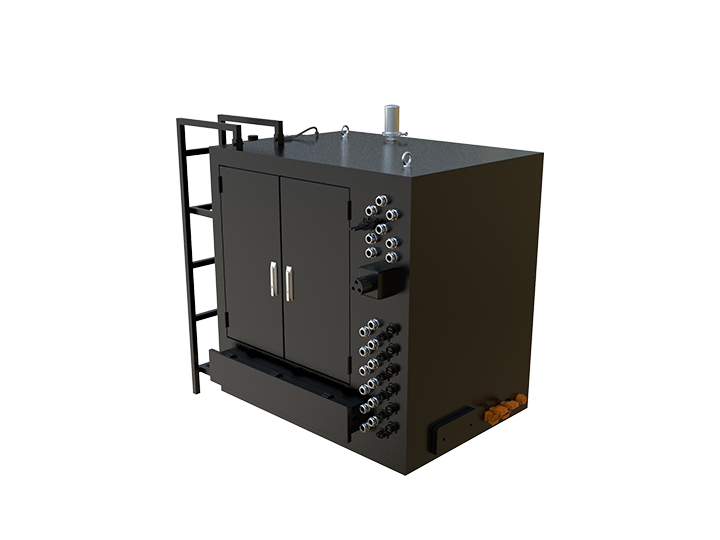

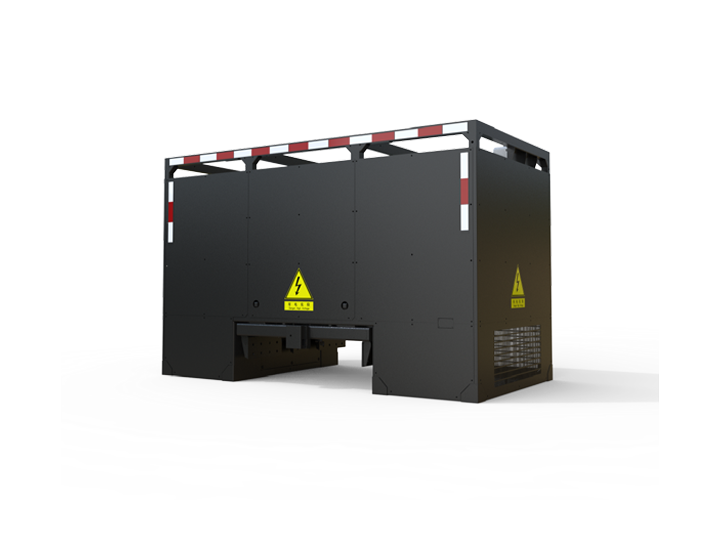

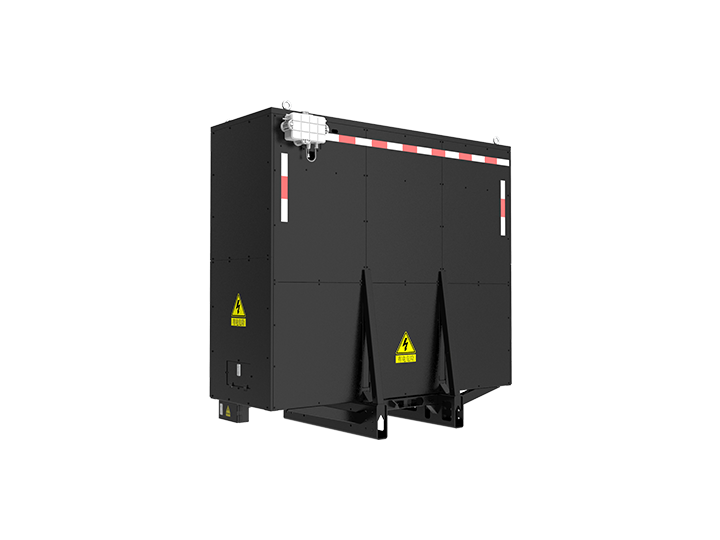

Closed design, waterproof, dustproof, moisture control, temperature control, efficient thermal management

Container design, pry loading design

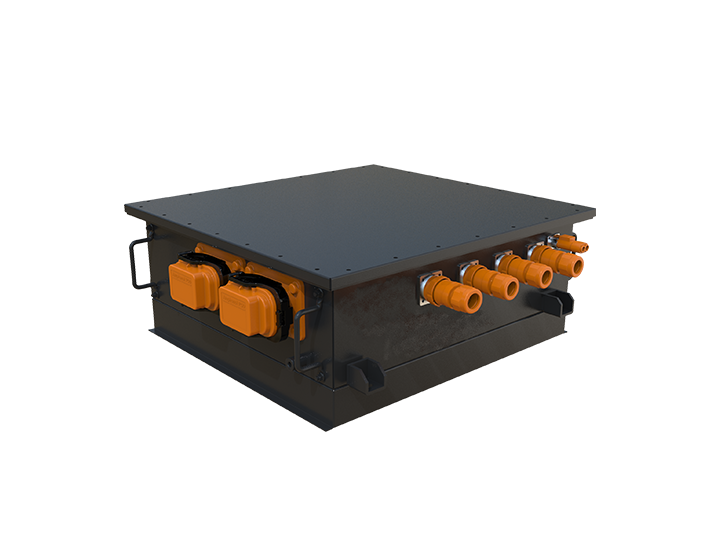

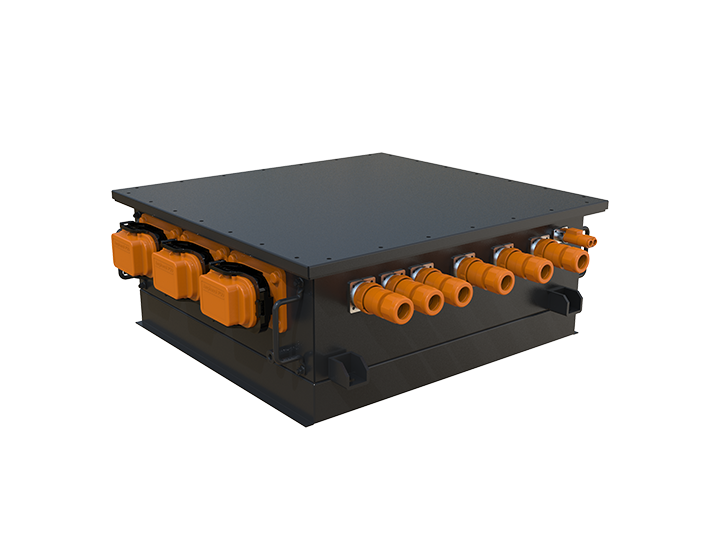

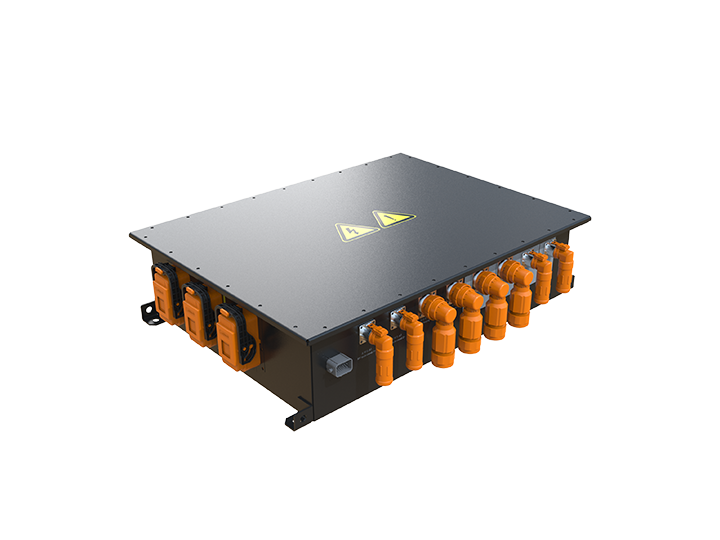

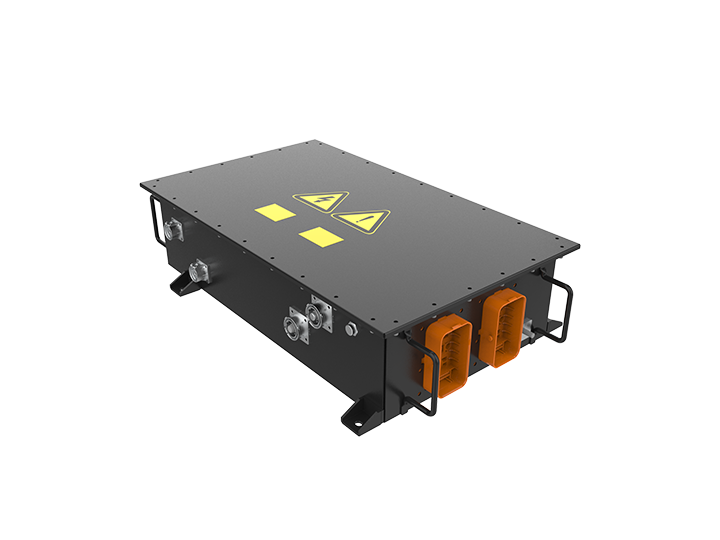

Fully compatible with mining card battery boxes below 1000kWh

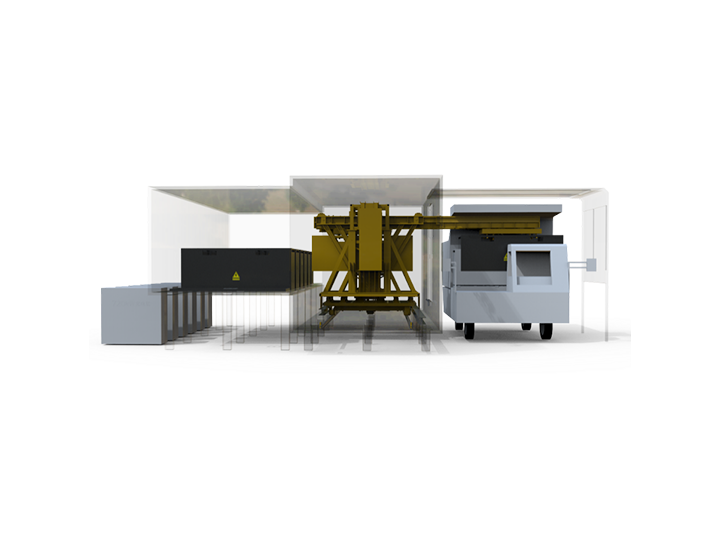

The rated lifting weight of the robot is 10 tons

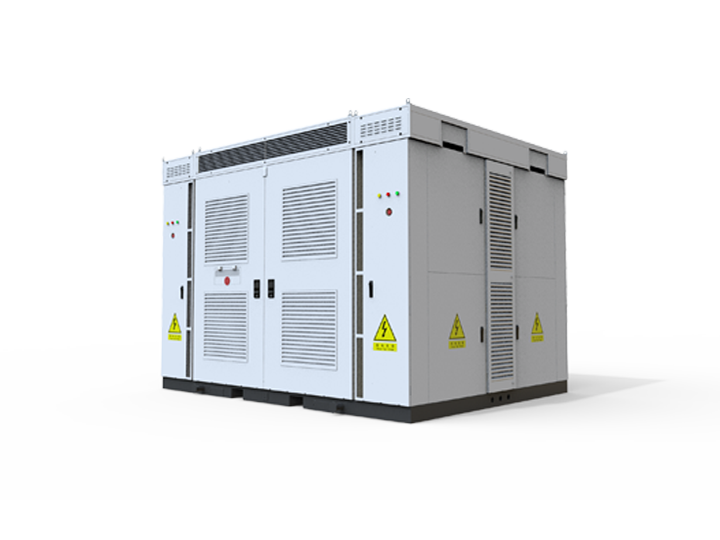

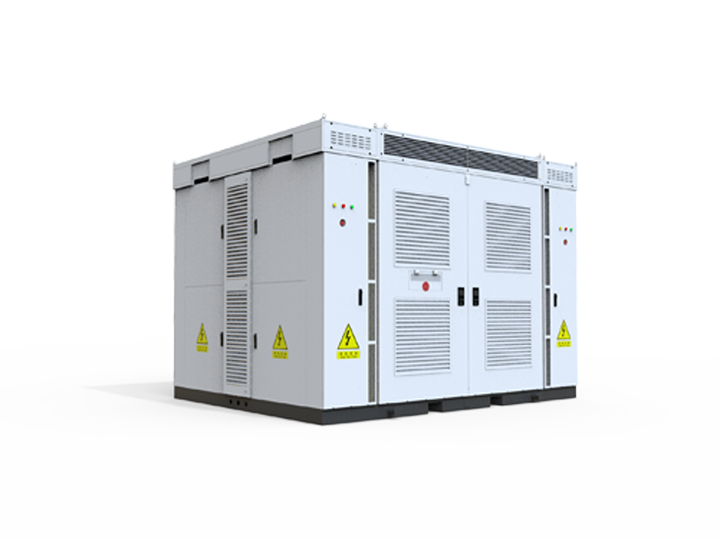

Excellent power sharing mechanism, compatible with multiple charging modes

Separation of charging and replacement for construction, low civil engineering requirements, no foundation pit

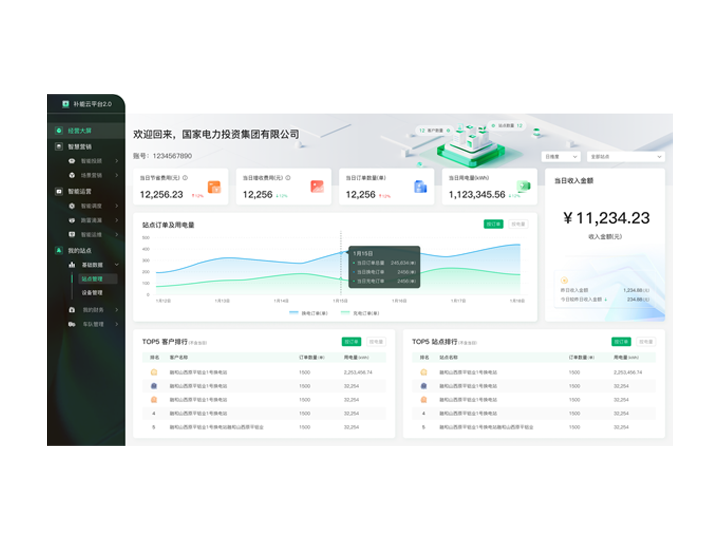

|

Battery Swap Mode

|

Side-Reaching Overhead Crane

|

|

Overall dimensions(m)

|

15.2m×10.7m×7.1m

|

|

Compatible Battery Types

|

528kWh/800kWh/1000kWh

|

|

Compatible Vehicle Models

|

Deck-type mining trucks, etc.

|

|

Each swap duration

|

≤6min

|

|

Theoretical Service Capability

|

75 times/20 hours

|

|

Charging Power

|

720kW

|

|

Battery Compartment

|

5 charging bays, 1 transfer bay, 1 firefighting bay

|

|

Operating ambient temperature

|

-20℃~55℃(High-Altitude Version-40℃)

|

|

Use elevation

|

≤2000m(High-Altitude Edition4000m)

|

|

Wind Resistance Grade

|

10/12 class(Working/Non-working status)

|

|

Seismic Resistance Grade

|

Seismic Design Intensity: 7 degrees,0.15g

|

|

Power supply demand

|

≥2×2500kVA

|

|

Vehicle Guidance and Positioning

|

Guidance: Guidance belt + LiDAR + LED display +

voice prompts Positioning: Servo laser scanning

|

|

Vehicle Identification

|

License Plate Recognition/RFID

|

|

Optional Equipment

|

External gun cable, high-capacity UPS, extreme cold weather kit,

high-altitude kit, high-saltmist kit, standalone guard booth

|